Welcome to contact +8613721698712

The small tempering furnace uses physical or chemical methods to form the compressive stress layer on the glass surface and form the tensile stress layer inside. When the glass is subjected to external force, the pressure stress layer can counteract the partial tensile stress and avoid the broken glass, thus achieving the purpose of improving the glass strength. Not only that, the micro cracks on glass surface become more subtle under this compressive stress, but also enhance the strength of glass to a certain extent.

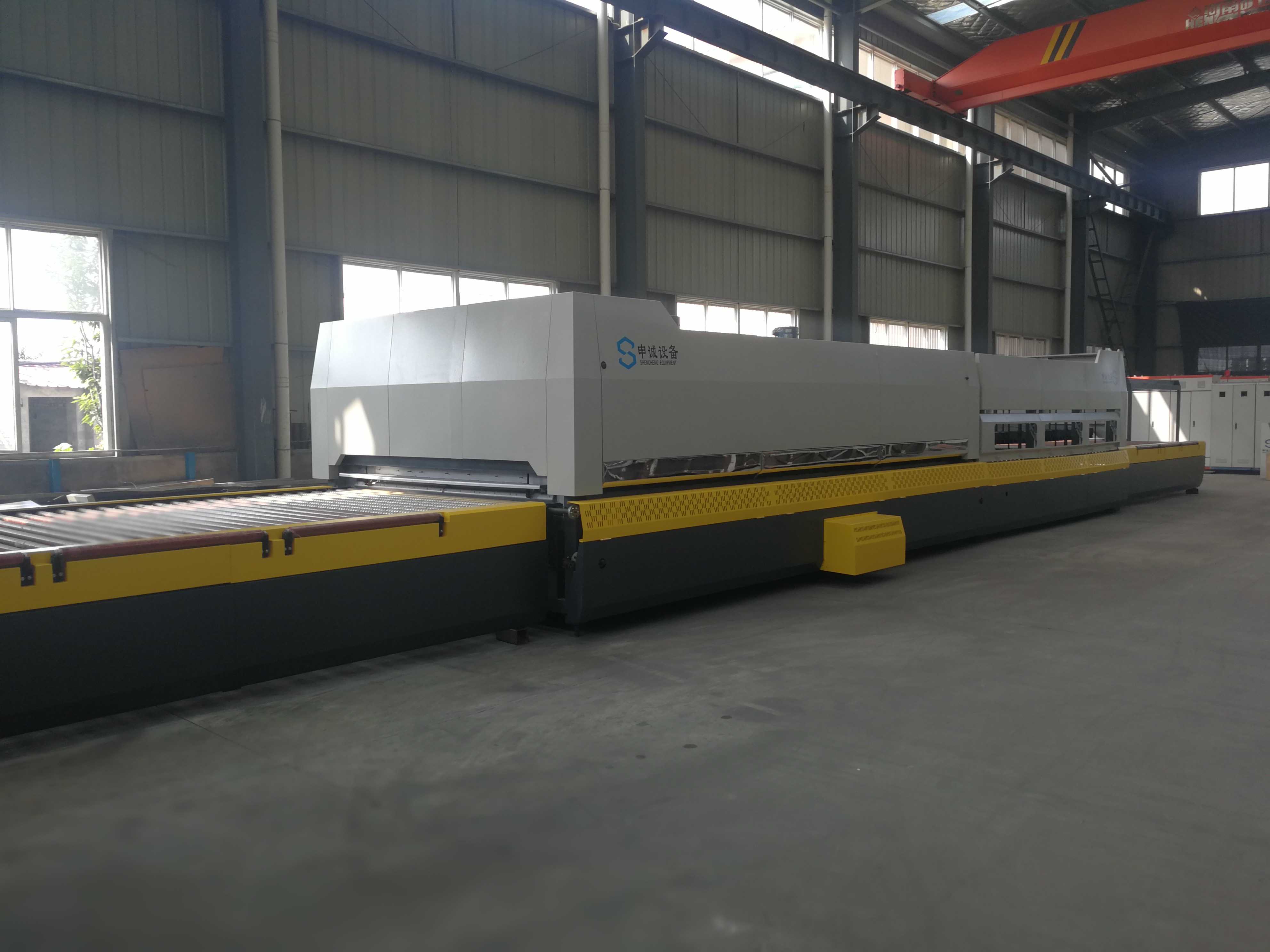

At present, the physical tempering method commonly used in Shin Cheng small tempering furnace is to heat the glass to the softening point (about 650 C), when the glass still keeps its original shape, but the particles in the glass have a certain ability to migrate to make the internal stress disappear quickly, and then the glass tempering furnace is tempered. When the glass is cooled, when the temperature is balanced, the glass surface produces a compressive stress, and the inner layer produces Zhang Yingli. That is, the glass produces a uniform and regular internal stress, which improves the tensile strength of the glass as a brittle material, thus improving the bending and punching strength of the glass. At the same time, due to the existence of the uniform stress inside the glass, once the glass part is damaged by the impact of the glass, the self explosion is small particles under the internal stress, which improves the safety of the glass. Therefore, tempered glass can also be called prestressed glass or safety glass.

In the process of tempering, the glass tempering furnace of the glass tempering furnace of glass tempering furnace in Luoyang generally produces wind spots and stress spots. The wind spot is formed in the cooling process, because of the uneven cooling of the glass, which is observed at a special angle and will see the bright and dark stripes on the glass surface. Stress spots are also caused by uneven stress. For example, during the heating process, the temperature difference between the hearth and the middle part causes uneven stress. There is no way to avoid stress spots at present. However, a well designed toughening equipment can reduce the visibility of stress spots.

“THE NEEDS OF THE USER ARE OUR PURSUIT”

Luoyang Shen Cheng Glass Technology Co., Ltd. is newly developed and made of small tempered equipment. It is cheap, time saving, electricity saving and labor saving are very suitable for the friends of the cabinet industry. We always adhere to good faith and help our customers

TEL:

18939008535 / 0379-61117177

E_MAIL:

linda@lywlglass.com

ADD:

Suhutuo Industry Zone, Wangcheng Bus Lane, Luoyang ,P.R. China