Welcome to contact +8613721698712

In the process control of the tempered glass of the glass tempering furnace, the rational parameter setting of the tempering furnace plays a decisive role in the quality and yield of the product. In setting each parameter, we must understand the function and the basis of the parameters and the interaction between the parameters. In order to ensure the realization of high quality technology. When the glass tempering furnace is tempered, we generally divide the toughening process into three aspects: heating, cooling, forming, and the relevant personnel of Luoyang Shen Cheng Glass Technology Co., Ltd. to introduce the setting of the process parameters in the cooling process of the glass in the tempering furnace.

1. Setting up the speed of the glass

The speed of glass output has great influence on the temperature of the glass when it is subjected to wind quenching. The slower the speed, the greater the heat loss of the glass during the transmission to the air-cooled section. As the thickness of the glass is thinner, the more strict the temperature requirements for the cooling quenching are required, so the setting of the furnace speed should be based on the thickness of the tempered glass and the size of the glass plate. The thinner the tempered glass is, the faster the furnace will be produced. For example, when the 5mm thick tempered glass is produced, the speed of the furnace is set to 500mm / s, and when the 6mm glass is produced, the speed of the glass can be lowered properly. The speed of the glass can be set at 450mm / s when the glass is produced. In accordance with the thickness of the glass, the setting of the furnace speed should also be referred to the size of the glass plate. For example, when it is made of the flat glass of the large plate, the improper setting of the speed of the furnace will result in the crack or the frying of the glass during the blow. This is due to the large plate surface and the slow speed, which causes the cooling of the front and rear end of the glass to be inconsistent. The result is.

2. Setting of glass cold swing speed

The cold swing speed has an effect on the uniform cooling of glass, and the unreasonable cold pendulum speed will lead to uneven fragmentation of the glass after toughening. The thinner the glass is, the stricter the wind pressure is required for the tempering. In order to achieve good tempering in each area of the glass surface, it is necessary to increase the cold swing speed of the glass in the air cooling section. The thicker the thickness of the glass, the cold swing speed of the glass can be reduced accordingly. For example, the cold swing speed of the tempered glass produced by 5mm thickness is 250mm / s, then the cold swing speed of the glass can be reduced to 200mm / S when the 6mm thick tempered glass is produced.

In addition, in the production of flexural glass, the setting of the cold swing speed should be based on the forming arc of the glass, the speed of the small cold swing of the molding radius is relatively fast, and the large forming radius can be relatively slow.

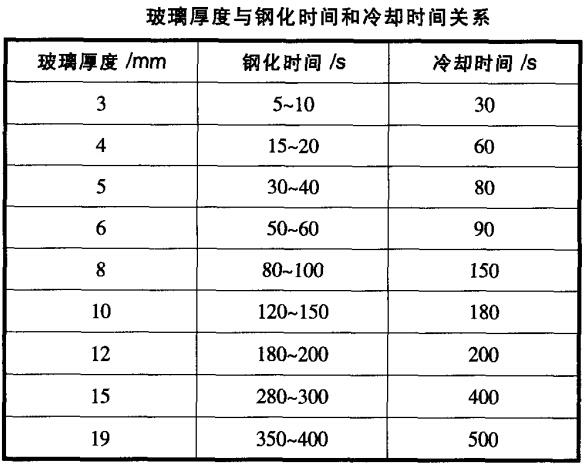

3. Setting of toughening time and cooling time

The cooling process of glass in air-cooled section is divided into two parts, namely, the quench section and the cooling section. The toughening time is the quenching time of the glass after the glass enters the air cooling section from the heating furnace. The tempering time is different from the cooling time of the glass. The tempering time plays an important role in the tempering degree of the glass. The quenching time is the process of forming the stress of the glass surface. The setting of the tempering time is mainly based on the thickness of the glass, the more the thickness is, the more the thickness is, the more thickness the thickness is. Thick, the longer the tempering time of the glass is. The main function of the cooling section is to reduce the surface temperature of the glass after the furnace. The temperature of the glass must be reduced to the contact temperature after the glass is out of the furnace. The setting of the tempering time and cooling time of the glass with different thickness can be referred to the table.

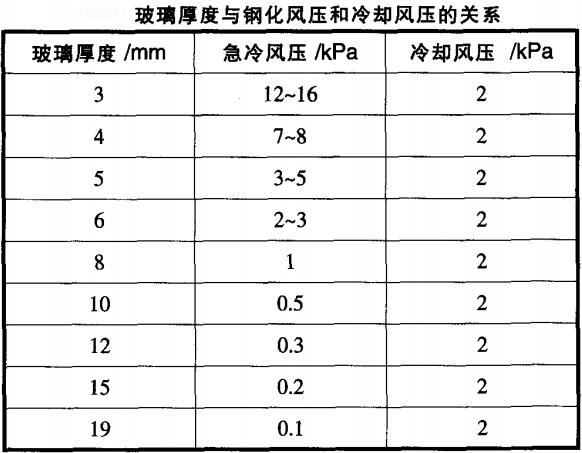

4, the setting of the steel wind pressure and the cooling wind pressure

The tempered pressure of the glass tempering furnace is one of the most important parameters in the technical parameters of the toughening process. The toughening pressure has a direct influence on the degree of tempering and the effect of the tempering. The setting of the steel wind pressure is based on the thickness of the glass. The thinner the glass is, the higher the requirement for the tempering pressure is, the steel wind pressure has been set up in the general assembly. On the other hand, it is necessary to refer to the color of glass and the opening and slotting of glass. The adjustment of the tempering wind pressure can be controlled on the computer, but the wind pressure of the upper wind gate and the wind pressure regulation of the lower wind gate generally need to adjust the guide plate of the central position of the upper and lower wind road. The diversion plate is located at the center position of the upper and lower wind road, which is used to adjust the wind pressure of the upper wind gate and the wind pressure of the lower wind gate, and to increase the upward wind to the upwind. The wind pressure of the grid decreases the wind pressure of the lower wind gate, and the downward pressure is to increase the pressure of the downwind grid and reduce the wind pressure of the upper grid. The main function of the cooling wind pressure is to reduce the temperature of the glass after tempering. It will not affect the degree of the tempering of the glass. The tempering pressure and the cooling pressure of the glass with different thickness can be referred to the following table.

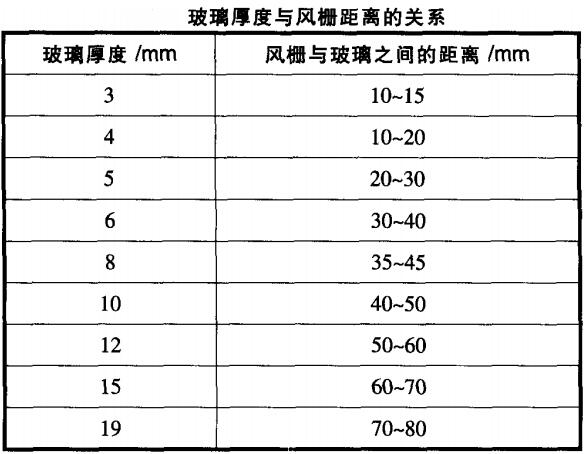

5. Setting the spacing of the windscreen in the glass tempering furnace

When the glass is cooled in the cooling section of a tempered furnace, the distance between the wind gate and the glass will affect the wind pressure on the surface of the glass. When the wind pressure is certain, the distance between the wind grid and the glass is smaller, and the wind pressure on the glass surface will be increased relatively. The number of debris, the mechanical strength and the safety performance will be obtained. On the other hand, if the distance between the wind grid and the glass increases, the wind pressure on the surface of the glass will be reduced relatively, the surface of the glass will be smaller, and the number of debris, the mechanical strength and the safety performance will be relatively poor. When the wind pressure is constant, we can adjust to a certain extent. The distance between the wind grid and the glass can be used to adjust the quality of the tempered glass, but the distance between the grid and the glass can not be adjusted blindly, and the stress spots on the surface of the glass will be increased after a small distance. The range of the distance between the windscreens and glass of different thickness of glass can be referenced to the following table.

“THE NEEDS OF THE USER ARE OUR PURSUIT”

Luoyang Shen Cheng Glass Technology Co., Ltd. is newly developed and made of small tempered equipment. It is cheap, time saving, electricity saving and labor saving are very suitable for the friends of the cabinet industry. We always adhere to good faith and help our customers

TEL:

18939008535 / 0379-61117177

E_MAIL:

linda@lywlglass.com

ADD:

Suhutuo Industry Zone, Wangcheng Bus Lane, Luoyang ,P.R. China